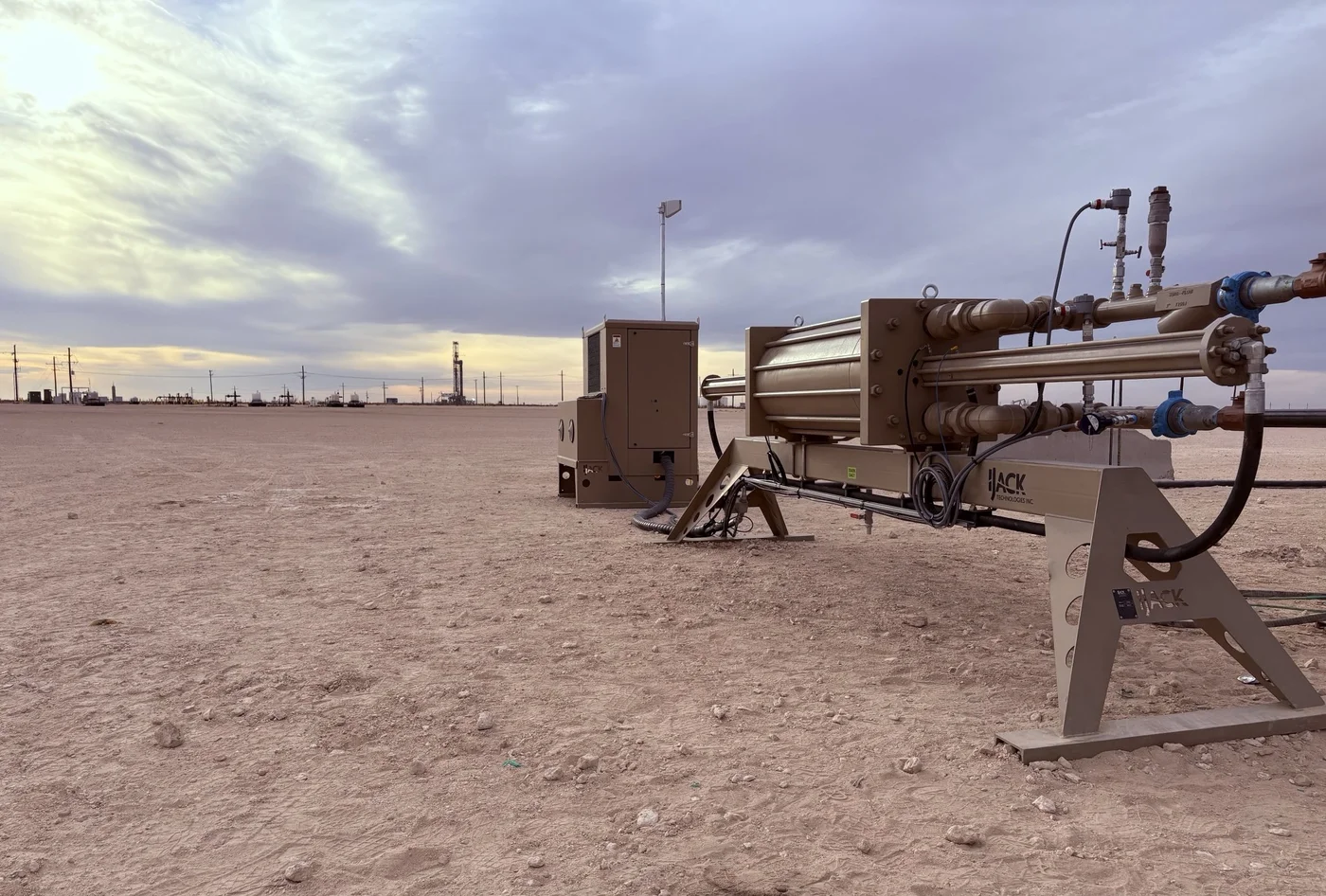

VRU™ Vapour Recovery Unit

Remove vapors. Keep tank top pressure to a minimum. Eliminate venting. Recover condensates.

IJACK™ VRU automated vapor recovery unit is designed to remove vapors from inside tanks keeping the internal tank top pressure to a minimum, sending recovered vapors and condensates to a facility. Simply tell EGAS-VRU the desired tank top pressure and it adjusts automatically to meet the goal.

A Simple Solution and Proven Business Case

- Eliminates / reduces emissions, venting and flaring

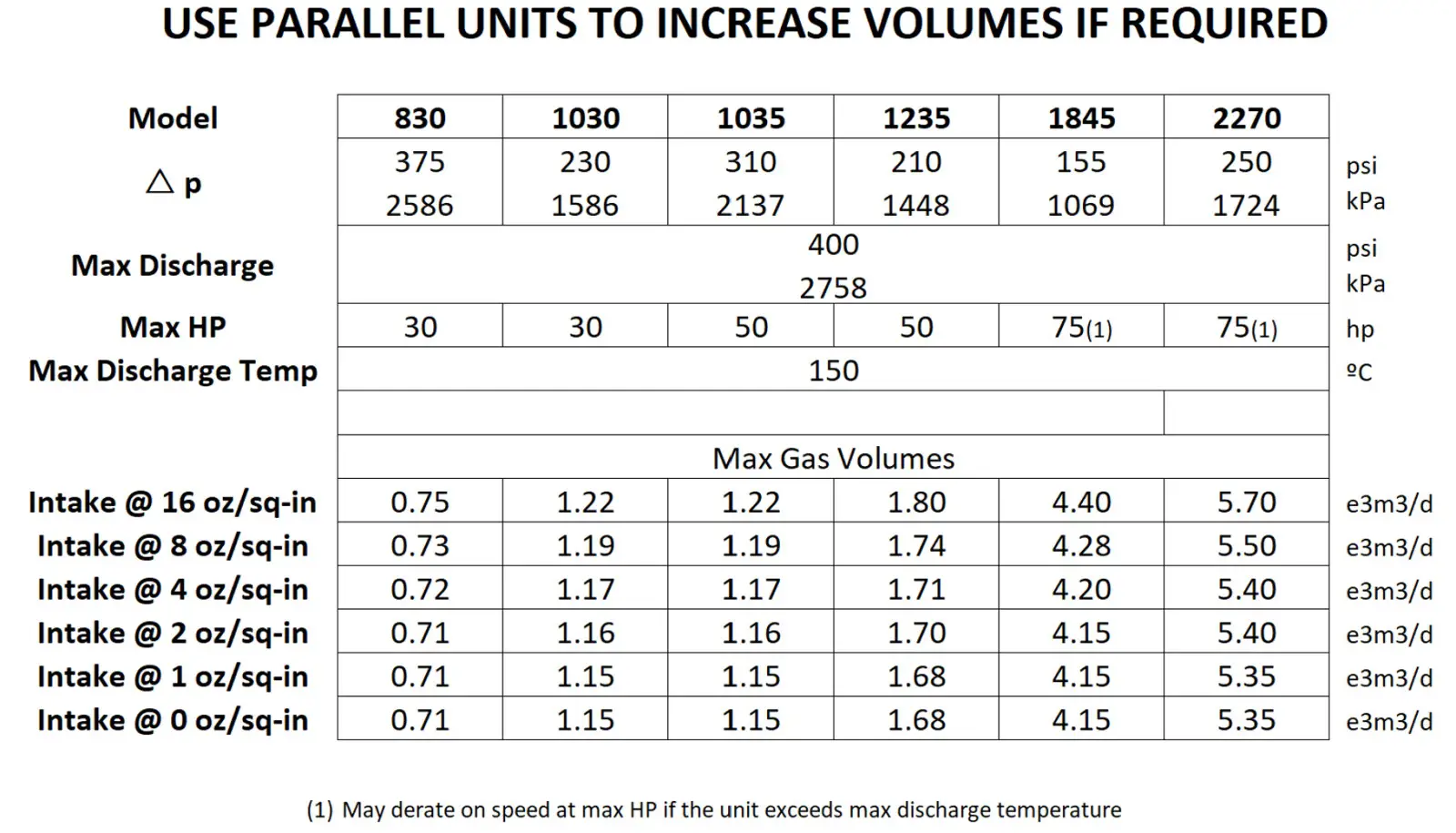

- Lowers tank top pressures as low as 0 psi / 0 oz/sq-in

- Handles vapors and associated fluids together without the need for knockouts or scrubbers, using one flowline to a facility

- Optionally discharge emulsions into a knockout, recovering and sending condensates to a tank and vapors to a gas sales line or compressor

- Minimal downtime, fewer maintenance intervals and completely field serviceable by local service crews

- Reciprocating pump with no bearings or gaskets which are damaged by butane, ethane, methane and propane requiring frequent rebuilds

- Increases bottom line by recovering condensates and eliminating carbon tax on emissions

- Eligible for government emission reduction grants

Features

- Fully automated to achieve and maintain set tank top pressure and discharge targets

- No site preparation required to place VRU

- Easily ties into existing tank top piping

- External ESD's can be tied into the VRU control system

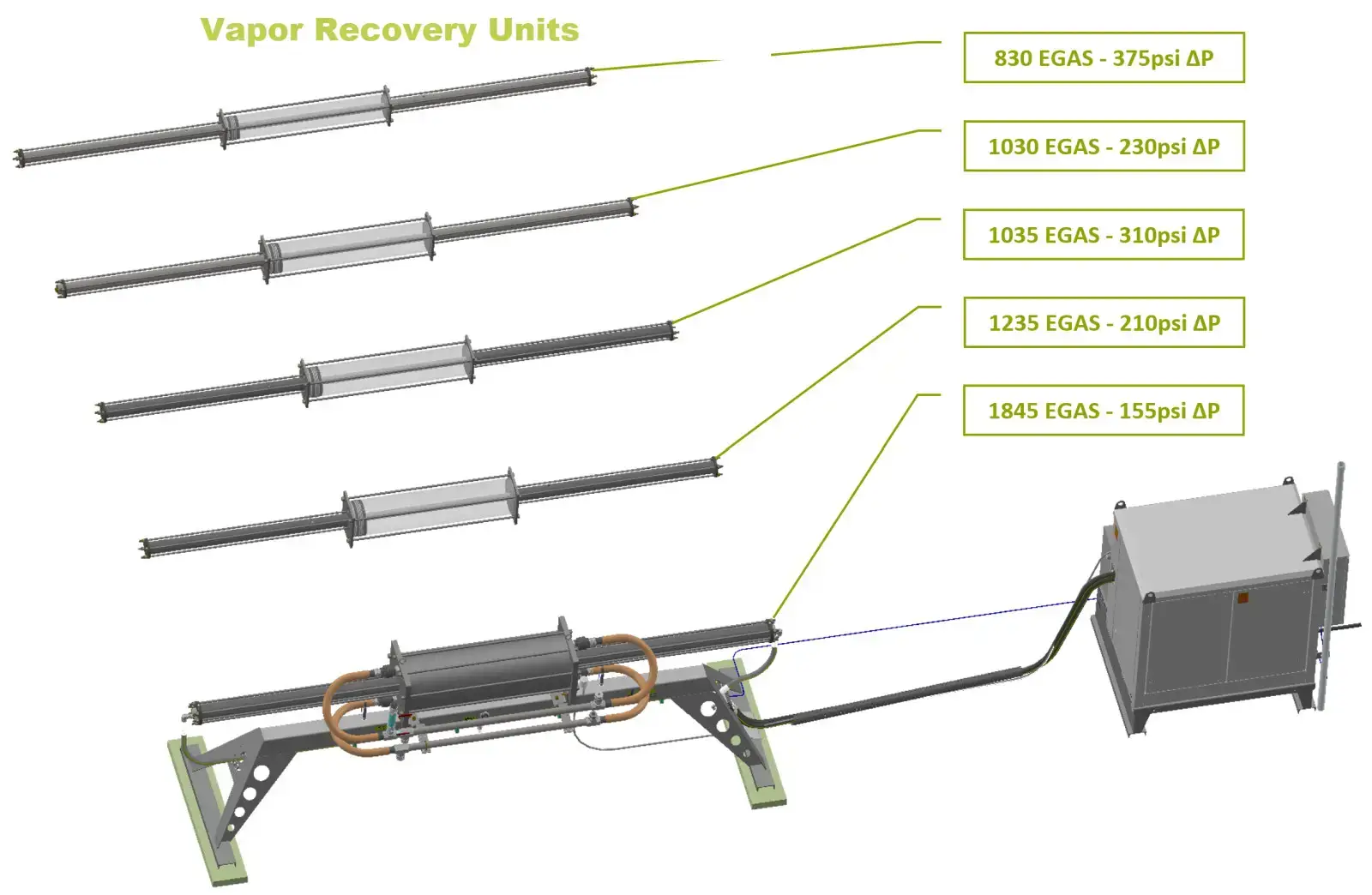

- Several models to choose from to optimize vapor volumes and intake / discharge pressures

- Fully serviceable and overhauled in the field in a few hours

- Compact footprint and engineered with premium connections

- Built with industry leading components, including prime motor, pump, seals, valves, etc

Patented Technology

IJACK's numerous Canadian and US patents include a position control system to maximize pump efficiency, and a buffer chamber (distance piece) that eliminates cross-contamination of the production and hydraulic fluids. The buffer chamber is also a safety feature which prevents gas from reaching the general rated power unit. You will only find these features on IJACK's products!

Keeping you on top of well performance.

No matter where your site is. No matter where you are. You are always in control. IJACK RCOM™ remote control and monitoring shows you precise, comprehensive, up-to-the-minute operating data, historical trends, compression cards, alarm logs and the ability to remotely control your units.

RCOM also includes an alerting system via email, SMS text messages, or phone calls to alert you of any problems such as power outages, or potential problems such as suction pressure spikes, and guide you on steps to be taken. Custom alerts can be created for any metric of interest, and configured from myijack.com.

Armed with this key information, you can analyze data and make the required changes to improve performance, efficiency and profitability.

Learn More About RCOM